Energy Efficiency Controller EEC

DIMAR-TEC's unique Energy Efficiency Controller EEC - Savings guaranteed!

Unique Sales Points

- 3-Year System Performance Warranty - Unmatched within the Industry

- Training Program for Customer's Installation Team

- "Remote Sea Trial" process

- Proof of Savings and Performance

- Crew's Sense of Responsibility supported by reports

- Most cost-efficient solution at the Highest Performance Level

- Payback 6 to 15 months

The EEC's unique concept will enable customer to instantly save upon installation.

But DIMAR-TEC is taking this to another level - SAVINGS ARE GUARANTEED or your money back.

With DIMAR-TEC's unique "remote sea trial" optimization strategy, each EEC will be fine-tuned to individual vessel

specifics - ensuring optimal performance and savings.

Due to their physical characteristics, circulating pumps in cooling water applications and engine room fans provide a considerable saving potential.

Small reductions of the pump speed leads to a major reduction in electric power usage.

Consequently, it generates energy and cost savings

All pumps on board a vessel with engine load dependent operation are consuming a large amount of energy unncessarily,

as the layout been made for 100% MCR and a Sea Water Temperature of 32°C.

All pumps on board a vessel with engine load dependent operation are consuming a large amount of energy unncessarily,

as the layout been made for 100% MCR and a Sea Water Temperature of 32°C.

Neither this cooling nor the air quantity will be demanded during normal operation, as the traditional vessel layout is made for 85% MCR.

However, the real operation profiles are usually considerably lower.

The cooling water pumps and engine room fans are sized according to the main engine size.

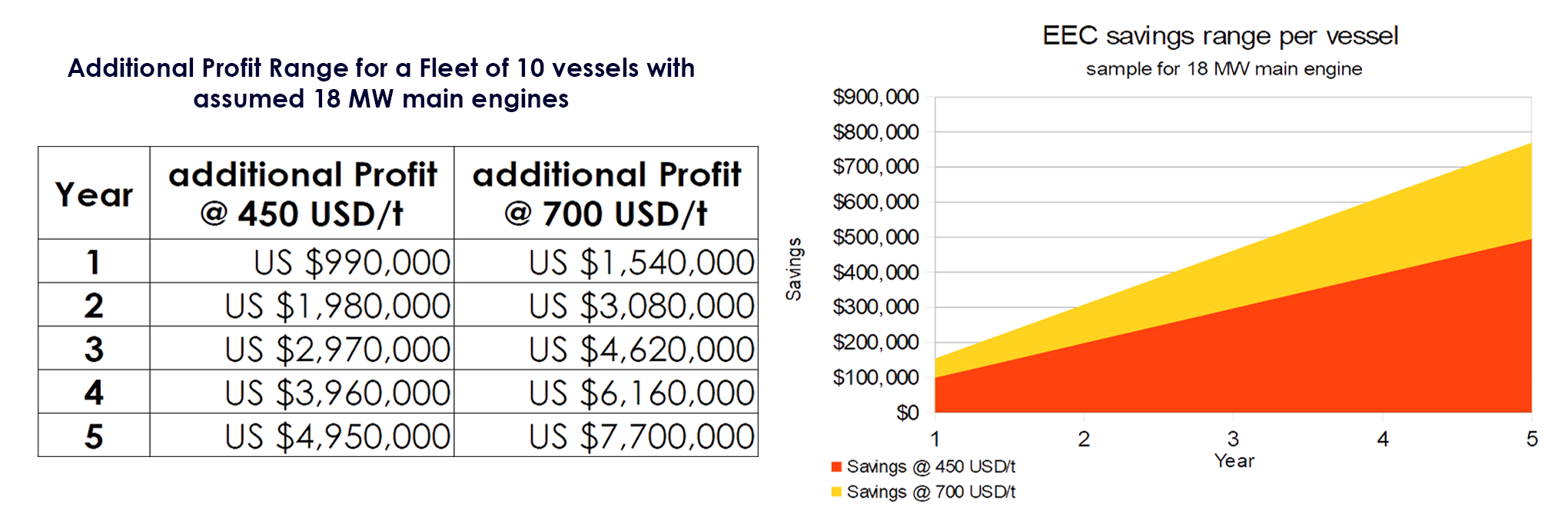

Typical savings for a sample vessel with 18 MW isntalled main engine are between 100.000 & 150.000 USD/ year, based on a fuel price range from

450-700 USD/ton (assumed costs for HFO and MDO).

This means a fleet of 10 vessels will save 1-1.5 Mio USD per year.

To harvest this potential DIMAR-TEC's EEC system integrates state-of-the-art Frequency Inverter technology with IP54 protection.

Our vessel-specific layout is designed to fit into smallest spaces and is perfectly suited for retroits in any existing engine room.

To harvest this potential DIMAR-TEC's EEC system integrates state-of-the-art Frequency Inverter technology with IP54 protection.

Our vessel-specific layout is designed to fit into smallest spaces and is perfectly suited for retroits in any existing engine room.

Alarm & Monitoring System Integration

For easiest crew handling, DIMAR-TEC's EEC system integrates seamlessly into existing vessel control systems where the crew continue to operate as before.

At the same time, cooling system temperatures and air supply to the engines are automatically controlled, key values and power consumption are recorded.

EEC performance short description:

- Fully automated control of cooling water pumps and engine room ventilation

- System developed for cost efficient retroit

- Seamless integration in existing Alarm- & Monitoring Systems

- Automated data recording ensures continous proof of performance and savings

- "Remote Sea Trial" procedure ensures optimum setup

- Uses proven industrial technology since decades

Savings Potential

- Guaranteed ongoing savings

- Payback in 6-15 months (depending on fuel & vessel operational profile)

- 2-8% savings of total fuel consumption

- Performance guarantee on SAVINGS RESULTS

Future technical development point of view:

- Modular design allows later system extensions. e.g. for LT pumps or DIMAR-TEC;s Fuel Efficiency Controller FEC

Operations

- Fully automated pump and fan control

- Automated operational data export

- Automated performance reports available

Installation / Commissioning / Certification

- Designed according to ISO 9001 requirements

- Simplest integratio in vessel IT

- 3-day training available for installation and commissioning by customer manpower - external service costs can be reduced to Zero

- Quality ensured with detailes vessel-specific process description by checklists and report templates

Value for money point of view: You decide!

Energy Efficiency Controller Executive Summary

Energy Efficiency Controller Executive Summary